- HYDRAULIC IRONWORKER

- HYDRAULIC IRONWORKER-EURO

- MECHANICAL IRONWORKER

- IRONWORKER ACCESSORIES

- PUNCHING MACHINE

- SHEARING MACHINE

- PRESS BRAKE

- CNC IRONWORKER

- LASER CUTTING MACHINE

- OTHER MACHINES

LATEST NEWS

- PRESS BRAKE FINALLY—THE BRAKE YOU’VE

- Ironworkers

- The use of bending machine

- Shear Spinning

- SHEARING OPERATION FUNDAMENTAL

- What is the best shearing machine?

CONTACT US

- ADD: Jingjiang City,Jiangsu Province,China

- TEL: +86-18994703330

- FAX: 86 523 84850330

- E-mail: lulu@cnapec.com

Ironworker AIW-120S

- Hydraulic Ironworker

- Type: AIW-120S

- Color: Optional

- ISO9001, CCC, CE

- Product description: Punching holes, Notching, Press brake, Bending, Pipe notching, Profile steel shearing (channel shearing, I-beam shearing, round/square bar shearing, flat bar shearing, steel plate shearing, angle stee

PRODUCT INTRODUCTION

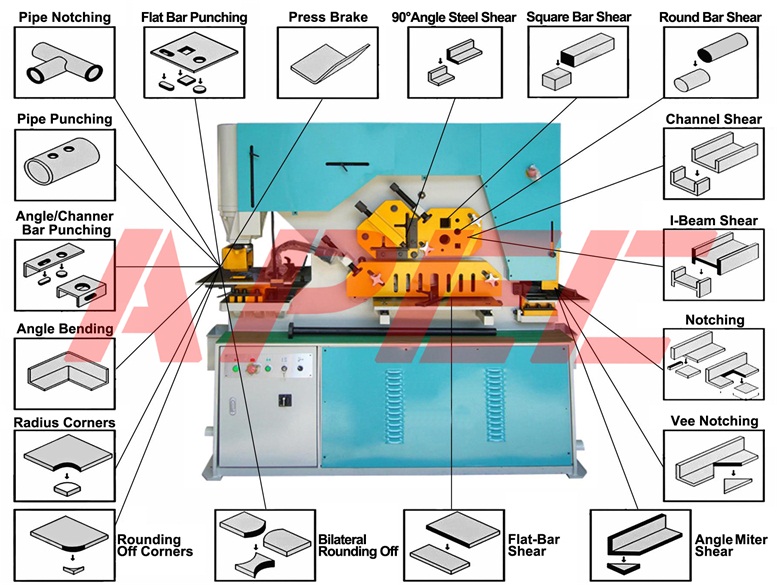

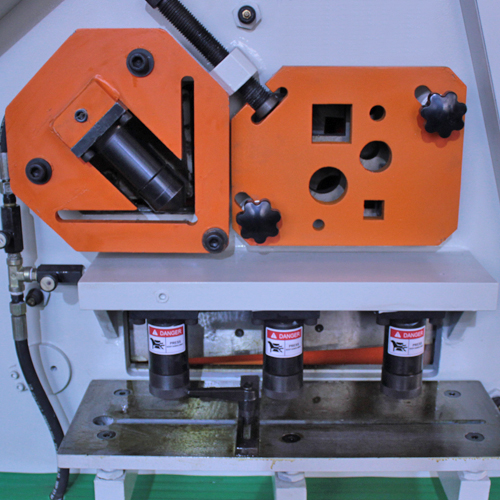

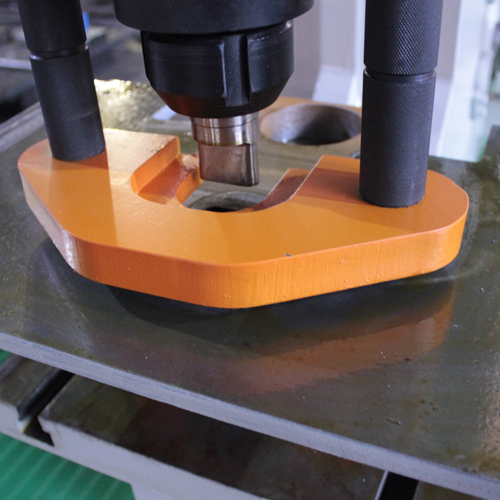

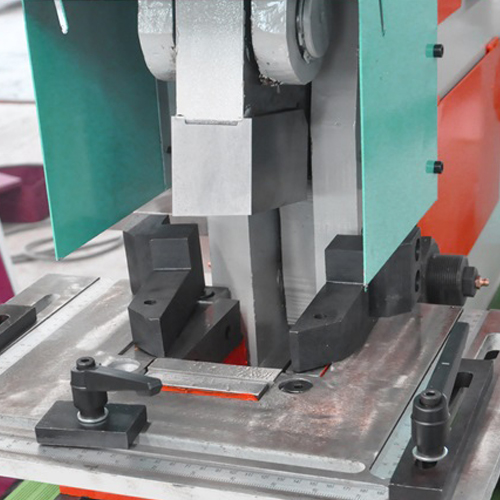

APEC Brand AIW series Ironworker features multiple functions, including: punching all kinds of holes (round hole, square hole, oblong hole), louver punching, steel plate punching, flat bar punching, angle steel punching, C-channel punching, H-beam punching, I-beam punching, profile steel shearing (channel shearing, I-beam shearing, round/square bar shearing, flat bar shearing, T-bar shearing, steel plate shearing, angle steel shearing), notching, press brake, angle steel notching , bending, pipe notching.

It comes standard with: quick-change coupling nut & sleeve, squaring arm with scale,gauging table with stops, punching base table, safety guards and more.We can design any special tools according to your metal fabricating requirements.

APEC Brand AIW-S series is improved machine on the base of standard AIW series. It goes along with automatic holding system and temperature cooling system.

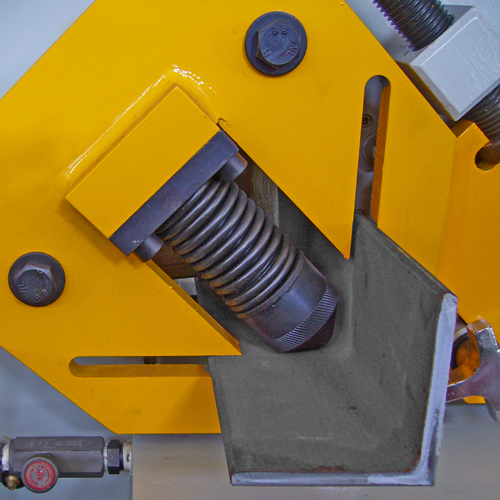

Automatic Holding System: There is automatic holding system in angle steel shearing and plate shearing work position. The holders will fix the position of work-piece, in this way, the accuracy is better and more safety for workers meanwhile save time and Improve working efficiency.

Temperature cooling system: Once start the machine,the cooling system starts working automatically.The hydraulic oil temperature always stays at 60 degree or less.It is applicable and safety for processing in quantities and long time.

Features

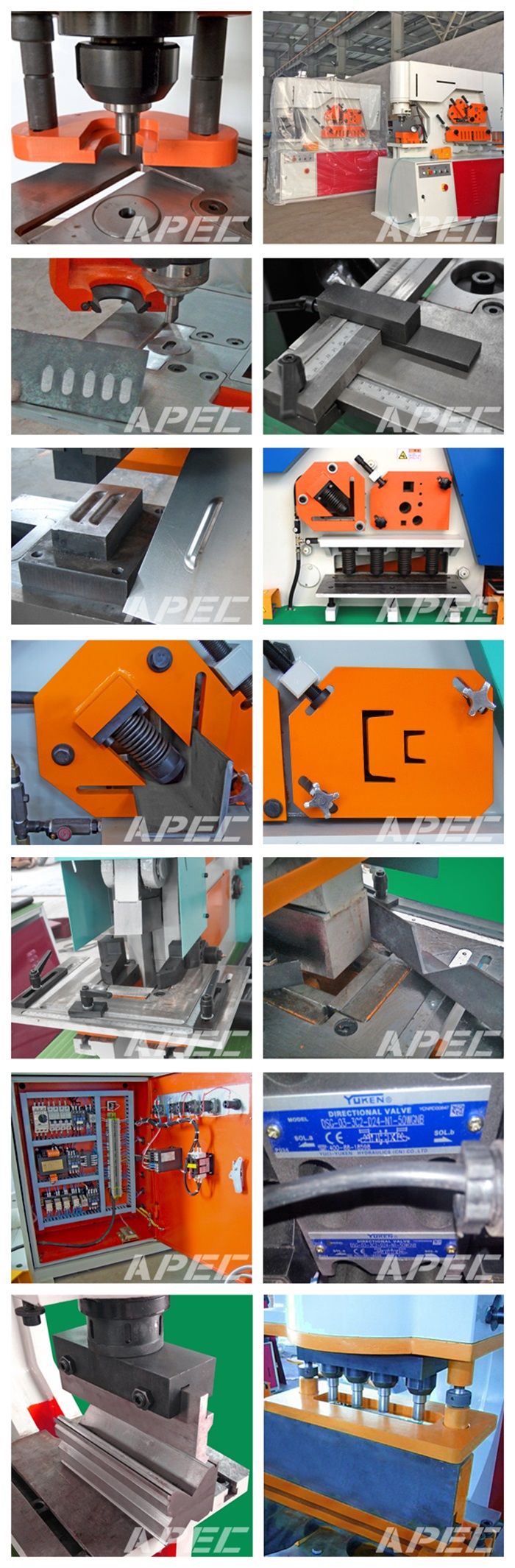

1. High Quality Components & System

a. Main Electrical component: Schneider

b. Valve: Yuken

c. Pump: Hydromax

d. Oil Seals: DZ

e. Timer Relay: OMRON

f. Motor: Siemens

2. Cost Effective

AIW SERIES Hydraulic Ironworker With Very good price/performance ratio

Various AIW SERIES Hydraulic Ironworker capacity from 45T to 400T to meet your requirement.

3. Stable Performance & Reliable Quality

AIW Series Hydraulic Ironworker use hydraulic transmission. Light weight, low noise, reliable performance.

4. Simple Operation

The operation of hydraulic ironworker is controlled by foot switch.

Technical Parameters:

|

Technical Parameter |

||||

|

No. |

Item |

Unit |

Value |

|

|

1 |

Hole Punching |

Punching Pressure |

KN |

1200 |

|

Max. Punching Thickness |

mm |

25 |

||

|

Max. Diameter of Punching |

mm |

35 |

||

|

Depth of Throat |

mm |

400 |

||

|

Max. Length of Cylinder Stroke |

mm |

80 |

||

|

Stroke Times |

times/min |

8-22 |

||

|

2 |

Flat-bar Shearing |

Angle of Shear |

degree |

8° |

|

Max. Shearing Thickness |

mm |

25 |

||

|

Flat Bar (W×T) |

mm |

600x16 |

||

|

330x25 |

||||

|

3 |

Angle Steel Shearing |

90° Shearing of Equal Angle Steel |

mm |

160x160x14 |

|

45°Shearing of Equal Angle Steel |

mm |

80x80x7 |

||

|

4 |

Profile Steel Shearing |

Round-bar |

mm |

60 |

|

Square-bar |

mm |

50x50 |

||

|

T-bar |

mm |

160x80x14 |

||

|

I-beam |

mm |

200/102x9 |

||

|

C-channel |

mm |

200x75x9 |

||

|

5 |

Notching |

Thickness |

mm |

14 |

|

Width |

mm |

57 |

||

|

Depth |

mm |

100 |

||

|

6 |

Material Tensile Strength |

N/mm2 |

450 |

|

|

7 |

Motor Power |

KW |

7.5 |

|

|

8 |

Overall Dimensions(L×W×H ) |

mm |

2350x980x2100 |

|

|

9 |

Gross Weight |

Kg |

4800 |

|

Note:Design and specifications subject to change without notice.

Accessories:

a. A pair of round hole punching die

b. A set of angle steel blade

c. A set of square and round bar blade

d. A set of shearing plate blade

e. A set of notching blade

The above punching and moulds will be installed in the machine.

For other dies and blades, customers need to order

Installation & Operation Training

APEC will provide you 1-7 day installation and operating training in our factory.

FAQS:

1. Payment Terms

T/T, L/C at sight are acceptable by us.

2. Price Terms

It is up to your requirement. EX-WORS, FOB, CIF, CFR and so on are acceptable by us.

3. Delivery Time

25 working days from our accountant confirm your deposit payment.

4. Shipment Condition

We will arrange the machine production from our accountant confirm your deposit payment. The deposit is 30% of the contract. The balance should be paid up before loading machines.

5. Warranty

13 months quality guaranty for the main spare parts, not include quick-wears parts, like blade, punch, die and so on. If the parts of machines have problems, which are caused by its own quality, we will provide the accessories for free.

lulu

lulu lulu

lulu