- HYDRAULIC IRONWORKER

- HYDRAULIC IRONWORKER-EURO

- MECHANICAL IRONWORKER

- IRONWORKER ACCESSORIES

- PUNCHING MACHINE

- SHEARING MACHINE

- PRESS BRAKE

- CNC IRONWORKER

- LASER CUTTING MACHINE

- OTHER MACHINES

LATEST NEWS

- PRESS BRAKE FINALLY—THE BRAKE YOU’VE

- Ironworkers

- The use of bending machine

- Shear Spinning

- SHEARING OPERATION FUNDAMENTAL

- What is the best shearing machine?

CONTACT US

- ADD: Jingjiang City,Jiangsu Province,China

- TEL: +86-18994703330

- FAX: 86 523 84850330

- E-mail: lulu@cnapec.com

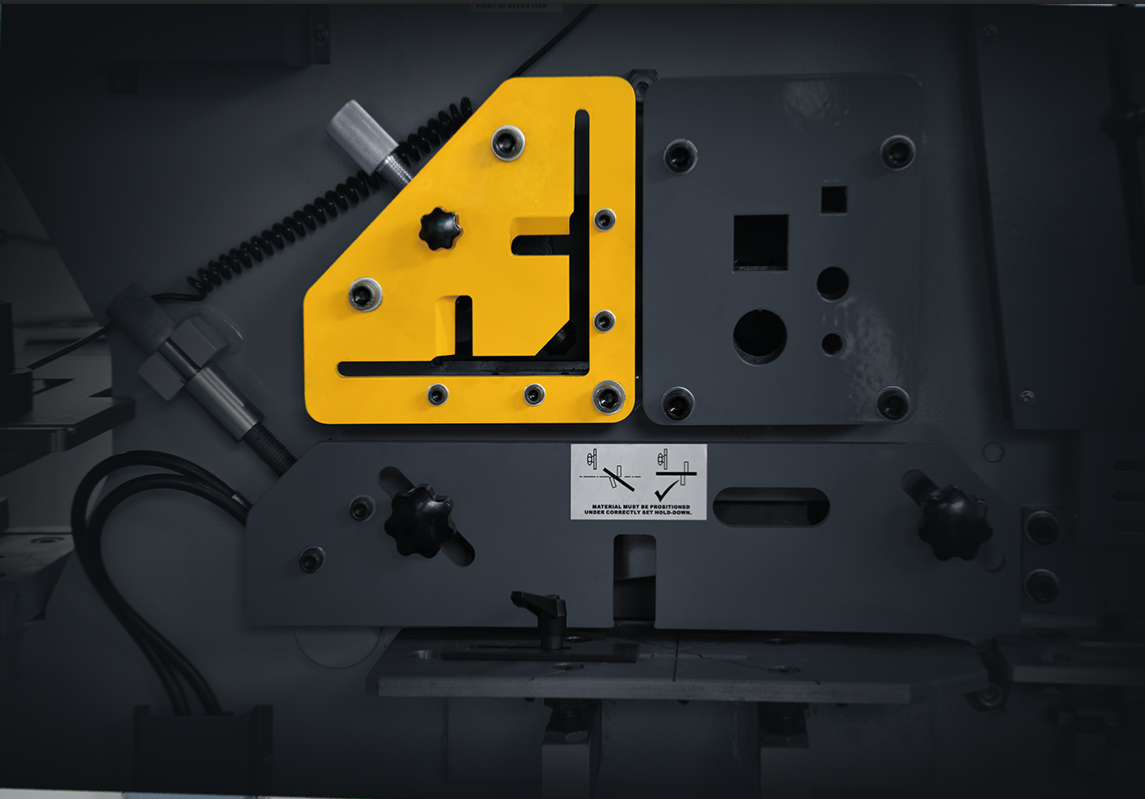

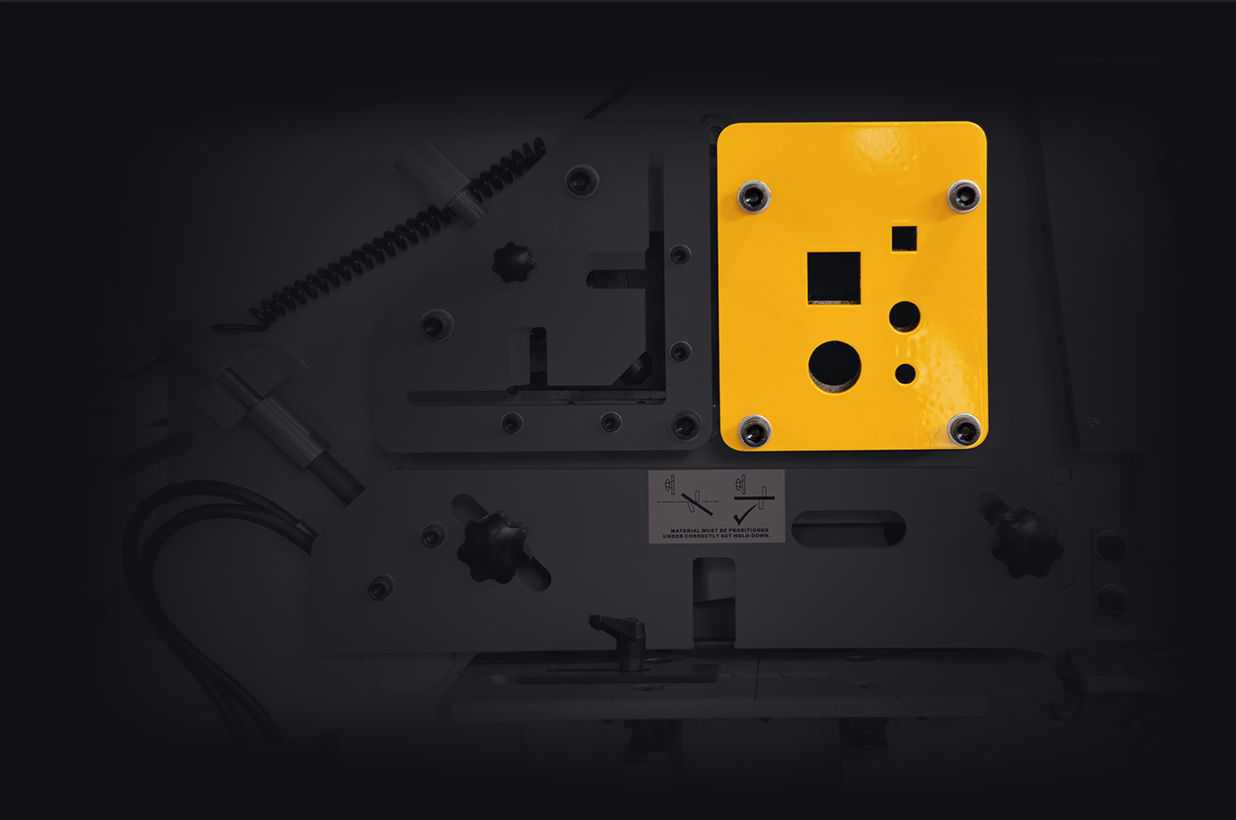

IRONWORKER ASW-95

- Product description: Punching holes, Notching, Press brake, Bending, Pipe notching, Profile steel shearing (channel shearing, I-beam shearing, round/square bar shearing, flat bar shearing, steel plate shearing, angle stee

PRODUCT INTRODUCTION

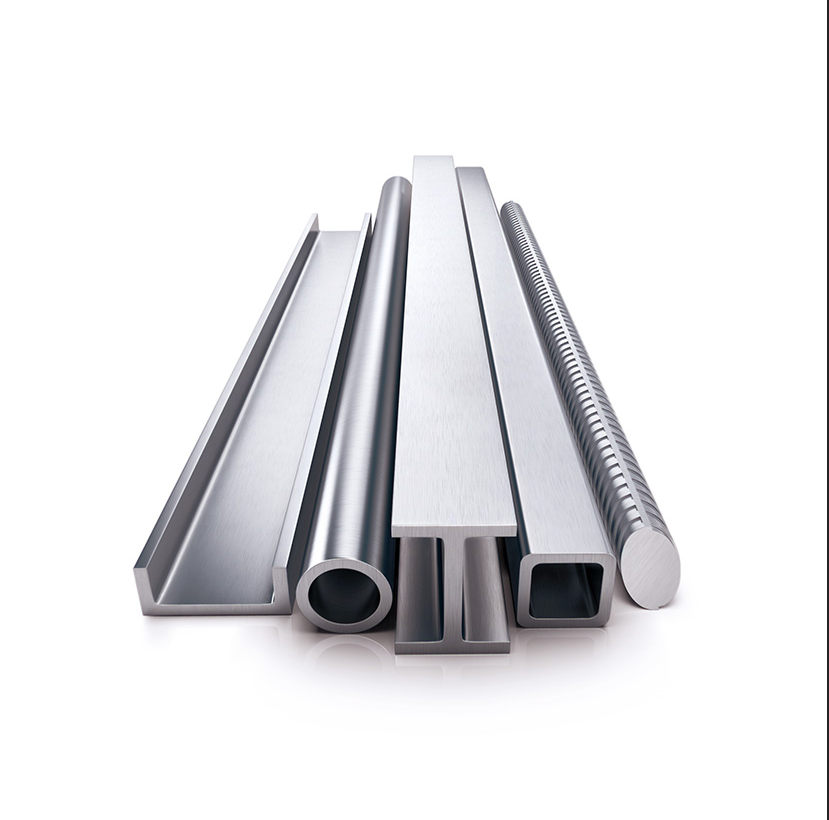

APEC Brand ASW series Ironworker features multiple functions, including: punching all kinds of holes (round hole, square hole, oblong hole), louver punching, steel plate punching, flat bar punching, angle steel punching, C-channel punching, H-beam punching, I-beam punching, profile steel shearing (channel shearing, I-beam shearing, round/square bar shearing, flat bar shearing, T-bar shearing, steel plate shearing, angle steel shearing), notching, press brake, angle steel notching , bending, pipe notching.

It comes standard with: quick-change coupling nut & sleeve, squaring arm with scale, gauging table with stops, punching base table, safety guards and more.We can design any special tools according to your metal fabricating requirements.

Features

1. High Quality Components & System

a. Main Electrical component: Schneider

b. Valve: Yuken

c. Pump: HY

d. Oil Seals: DZ

e. Connector: PAKER

2. Cost Effective

ASW SERIES Hydraulic Ironworker With Very good price/performance ratio

Various AIW SERIES Hydraulic Ironworker capacity from 45T to 175T to meet your requirement.

3. Stable Performance & Reliable Quality

ASW Series Hydraulic Ironworker use hydraulic transmission. Light weight, low noise, reliable performance.

4. Simple Operation

The operation of hydraulic ironworker is controlled by foot switch.

Technical Parameters:

ITEM

UNIT

VALUE

Punching

Max. Capacity

mm

27x25

Dia.x Thi.

mm

57x12

Stroke Length

mm

80

Standard Throat Depth

mm

355

Deep Throat Model

mm

625

Largest Hole - std. euipment

mm

57

Largest Hole(Optional)

mm

160

Max. Height

mm

1040

Shearing

Flat bar- Max. Thickness

mm

380x20

Flat bar- Max. Width

mm

480x15

Angle Flange Trim-Max. 45°

mm

120x15

Working Height

mm

890

Angle Shearing

90° Shearing

mm

150x15

45° Mitre (true int./ext.)

mm

80x10

Working Height

mm

1155

Profile Shearing

Round/Square

mm

50

Channel/Beam

mm

160x90

Tee

mm

100x12

Notching

Material Thickness

mm

13

Width - Rectangle

mm

52

Depth - Rectangle

mm

100

Depth- Vee

mm

70

Angle Flange - Max. profile

mm

100x13

Working Height

mm

890

Cornor Notching

Maximum Capacity

mm

250sqx2

Tube Notch

Maximum outside dia.

mm

108

Bending

Bar Bend Max. Capacity

mm

250x20

Sheet Bend Max. Capacity

mm

500x3

Punching at notch Station

Throat Depth

mm

125

Maximum Cpacity

mm

38x10

Technical Data

Motor Power

KW

7.5

Net Weight- st. Throat

KG

2400

LxWxH

mm

1900x79x191

lulu

lulu lulu

lulu